In industries where materials are subjected to extreme conditions, such as chemical exposure, temperature fluctuations, and corrosive atmospheres, the selection of durable components is paramount for ensuring operational reliability and safety.

Pultruded fiber-reinforced polymer (FRP) profiles, manufactured through a continuous process that combines reinforcing fibers with thermosetting resins, offer exceptional performance in such demanding settings.

This article examines the inherent properties that render pultruded FRP profiles particularly suitable for harsh environments, supported by industry insights and practical applications.

Understanding Pultruded FRP Profiles

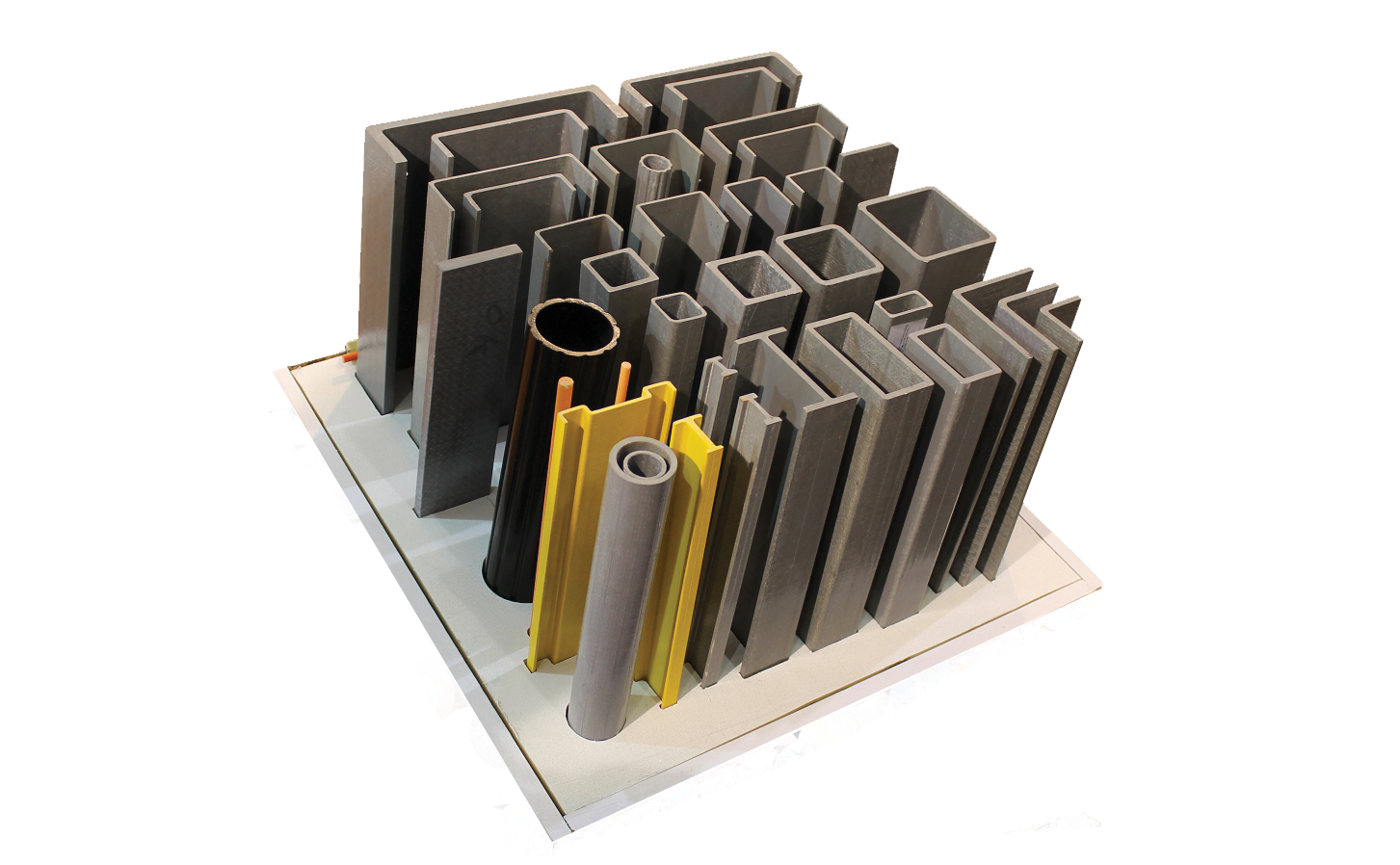

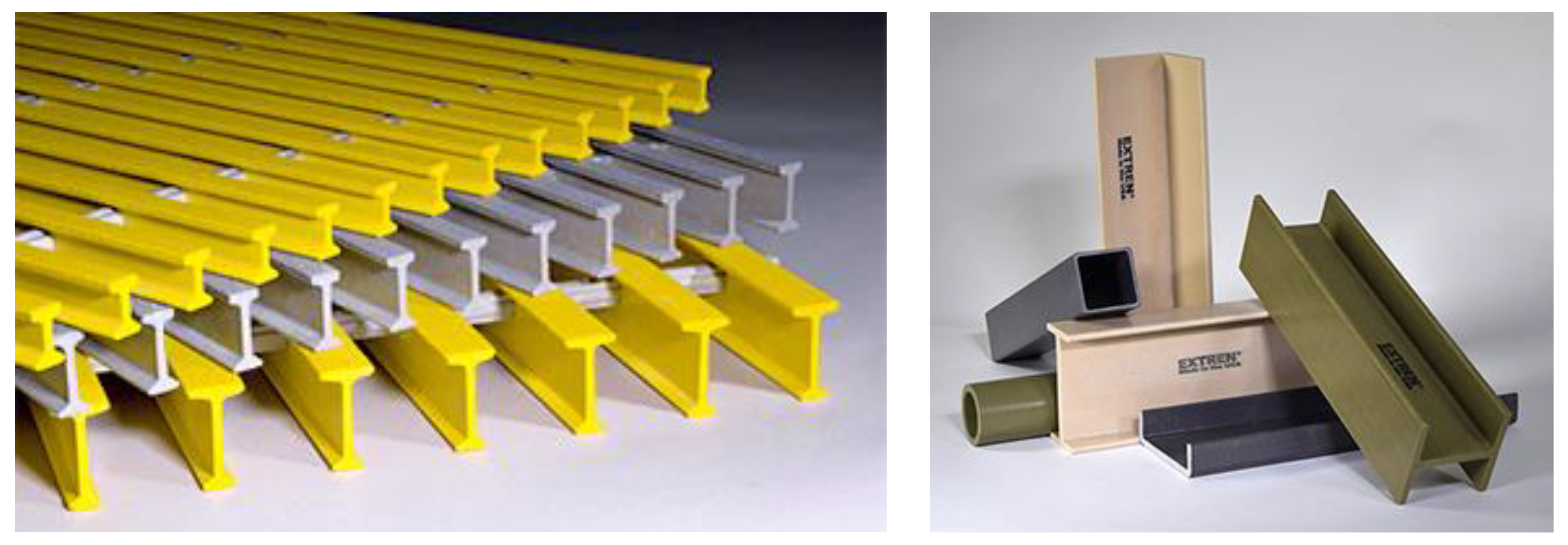

Pultrusion involves drawing continuous fibers, typically fiberglass, through a resin bath for impregnation, followed by shaping and curing in a heated die to produce consistent profiles such as beams, channels, and rods.

Modern advancements incorporate multi-directional reinforcements, including mats and fabrics, to enhance strength across multiple axes, moving beyond traditional unidirectional designs.

These profiles are engineered for applications requiring resilience against environmental stressors, making them a preferred alternative to metals like steel or aluminum in sectors such as chemical processing, marine infrastructure, and renewable energy.

Corrosion Resistance: A Core Advantage

One of the primary reasons pultruded FRP profiles excel in harsh environments is their superior corrosion resistance. Unlike metals, which can degrade rapidly when exposed to aggressive chemicals, salts, or moisture, FRP maintains structural integrity without rusting or pitting.

This property is particularly beneficial in chemical plants and offshore platforms, where exposure to acids, alkalis, and saline conditions is routine. For instance, FRP pultruded gratings and profiles demonstrate long-term stability in environments that would compromise traditional materials, reducing maintenance needs and extending service life.

Thermal Stability in Extreme Temperatures

Pultruded FRP profiles exhibit remarkable thermal stability, retaining mechanical properties across a wide temperature range, from sub-zero conditions to elevated heat. This resilience stems from the composite's low thermal conductivity and resistance to thermal expansion, which prevents warping or cracking under cyclic temperature changes.

In applications such as cooling towers or arctic installations, where materials must withstand freezing and thawing or intense heat, FRP outperforms metals that may become brittle or lose strength.

Studies on glass fiber-reinforced polymer (GFRP) pultrusions confirm sustained bending and compressive performance even after prolonged exposure to harsh thermal environments.

Mechanical Strength and Durability

The high strength-to-weight ratio of pultruded FRP profiles ensures robust mechanical performance without excessive mass. With tensile strengths comparable to or exceeding structural steel on a pound-for-pound basis, these profiles provide excellent impact resistance and fatigue endurance.

Incorporation of multi-directional fibers further bolsters transverse strength, making them suitable for load-bearing structures in extreme conditions. In seismic-prone or high-wind areas, FRP's flexibility and dimensional stability contribute to enhanced safety and longevity.

Lightweight Nature and Ease of Installation

Weighing significantly less than equivalent metal profiles—often 75% lighter—pultruded FRP facilitates easier transportation, handling, and installation in remote or challenging locations.

This attribute reduces labor costs and minimizes structural loads, which is advantageous in elevated platforms or marine environments where weight is a critical factor. Additionally, FRP's non-conductive properties provide inherent electrical insulation, ideal for utility and electrical applications in harsh, conductive settings.

Applications in Harsh Environments

Pultruded FRP profiles find extensive use in sectors exposed to extreme conditions. In the oil and gas industry, they serve as gratings, handrails, and structural supports resistant to corrosive hydrocarbons and saltwater. Marine applications, including bridges and piers, benefit from FRP's resistance to biofouling and wave impact.

In aerospace, pultruded components withstand high-altitude extremes and thermal stresses. Other uses include walkways in chemical facilities, ladder systems in industrial plants, and enclosures in electrical substations, where fire-resistant resins add further protection.

| Property | Benefit in Harsh Environments |

|---|---|

| Corrosion Resistance | Prevents degradation in chemical and saline exposures. |

| Thermal Stability | Maintains integrity in extreme temperatures. |

| Mechanical Strength | Offers high load-bearing capacity and durability. |

| Lightweight Design | Reduces installation costs and structural demands. |

| Electrical Insulation | Ensures safety in conductive or electrical settings. |

Conclusion

Pultruded FRP profiles represent a versatile and reliable solution for harsh environments, combining corrosion resistance, thermal stability, and mechanical robustness to outperform traditional materials in demanding applications. Their adoption not only enhances operational efficiency but also contributes to long-term cost savings through reduced maintenance and extended lifespan.

For organizations seeking custom pultruded solutions tailored to specific environmental challenges, consulting with specialists ensures optimal material selection and performance.