The automotive and aerospace industries face increasing pressure to enhance performance, reduce environmental impact, and comply with stringent regulations on fuel efficiency and emissions. Pultruded fiberglass, produced through a continuous process that yields high-strength, lightweight composite profiles such as tubes, rods, angles, and custom shapes, has emerged as a transformative material.

By offering a superior strength-to-weight ratio compared to traditional metals like steel and aluminum, pultruded fiberglass enables significant lightweighting while maintaining structural integrity.

This article examines the key benefits of pultruded fiberglass—particularly in weight reduction, fuel efficiency, and emissions reduction—along with specific component applications driving its adoption in these high-demand sectors.

Lightweighting Benefits: A Core Advantage Over Metals

Pultruded fiberglass provides exceptional strength-to-weight performance, often achieving 60–75% weight savings compared to steel while delivering comparable or superior tensile and flexural strength in preferred directions. This anisotropic property allows engineers to optimize fiber orientation for load-bearing requirements, resulting in efficient designs that minimize material use.

In contrast to metals, which exhibit isotropic properties and higher density, fiberglass composites reduce overall component mass without compromising durability. These savings translate directly into improved vehicle dynamics, extended range in electric vehicles, and enhanced payload capacity in aircraft.

The following images illustrate examples of lightweight pultruded fiberglass structural profiles commonly employed in transportation applications:

Fuel Efficiency and Emissions Reduction

Weight reduction directly correlates with lower energy consumption. In internal combustion engine vehicles, every kilogram saved improves fuel economy, while in electric vehicles (EVs), it offsets battery mass, extending driving range. Industry analyses indicate that pultruded composites can reduce vehicle weight by up to 30%, enhancing fuel efficiency and supporting compliance with global emissions standards.

For aerospace applications, lighter structures reduce fuel burn and enable greater payload or range. Pultruded fiberglass profiles support these gains through corrosion resistance and fatigue performance, minimizing maintenance and extending service life.

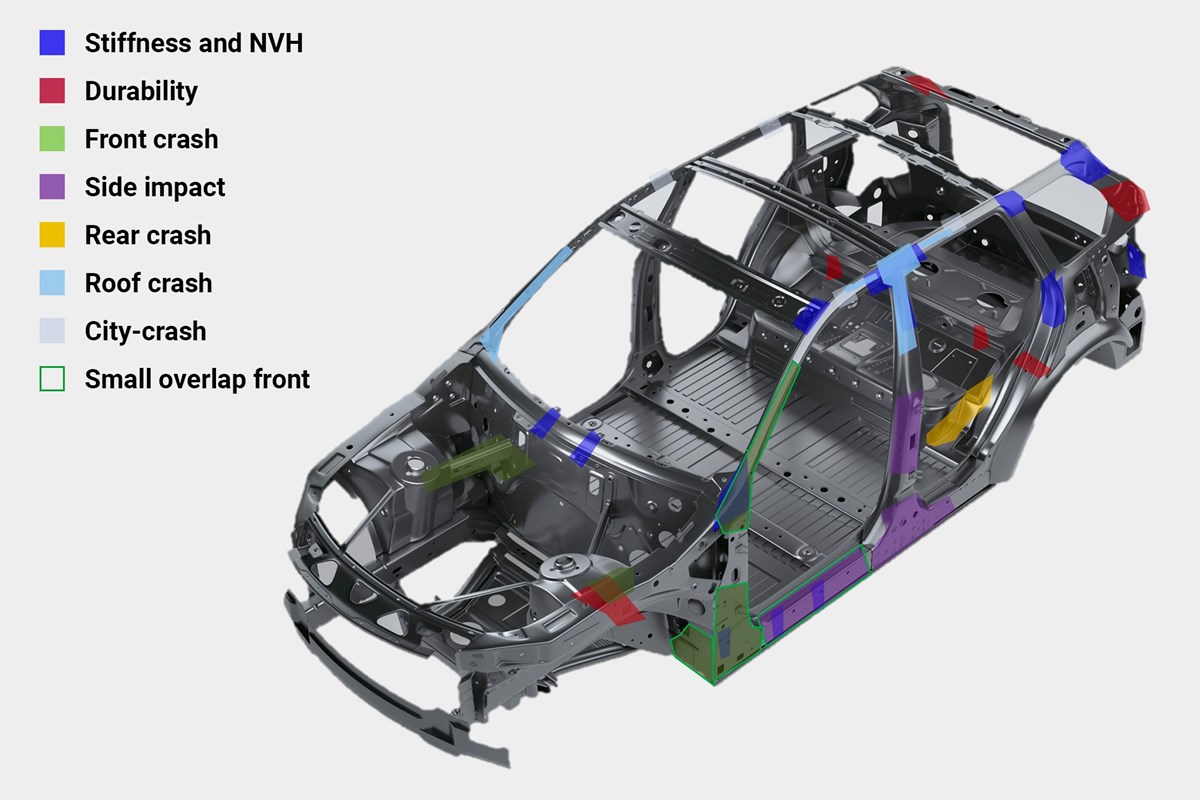

The image below depicts pultruded fiberglass components in automotive contexts, highlighting their role in structural reinforcements:

Specific Components in Automotive Applications

In the automotive sector, pultruded fiberglass is increasingly utilized for high-volume, performance-critical parts. Key examples include:

- Bumper beams — Providing energy absorption and crash management with progressive failure characteristics superior to steel in certain designs.

- Battery enclosures for EVs — Offering lightweight protection that offsets battery weight and enhances range.

- Structural reinforcements such as chassis rails, door intrusion beams, and front-end supports — Delivering stiffness and impact resistance at reduced mass.

These applications align with electrification trends, where weight savings are essential for meeting efficiency targets.

Specific Components in Aerospace Applications

Aerospace demands prioritize minimal weight alongside high strength and environmental resistance. Pultruded fiberglass contributes to:

- Interior structures and secondary components — Reducing overall aircraft mass for improved fuel efficiency.

- Cargo systems and satellite elements — Benefiting from 60–70% weight reductions compared to aluminum.

- Structural supports — Enabling durable, fatigue-resistant profiles for demanding flight conditions.

Conclusion

Pultruded fiberglass is revolutionizing the automotive and aerospace sectors by delivering substantial lightweighting advantages that enhance fuel efficiency, reduce emissions, and support sustainability goals. Its adoption in critical components underscores a shift toward high-performance composites that outperform traditional metals in weight-sensitive environments.

At Tencom, we specialize in custom pultruded fiberglass solutions tailored to the precise requirements of automotive and aerospace applications. Our expertise ensures optimal material performance, from resin selection to profile design. Contact our engineering team today to discuss how pultruded fiberglass can advance your next project toward greater efficiency and innovation.

Post Summary

This article explores the transformative role of pultruded fiberglass in the automotive and aerospace sectors, emphasizing its superior strength-to-weight ratio for lightweighting, which achieves 60–75% weight savings over metals like steel and aluminum while maintaining structural integrity. Key benefits include enhanced fuel efficiency, reduced emissions, and compliance with regulatory standards, driven by applications such as bumper beams, battery enclosures, vehicle chassis reinforcements, and interior structures, cargo systems, and structural supports in aircraft.

Pultruded fiberglass, produced via a continuous composite process yielding profiles like tubes and rods, supports electrification trends in electric vehicles and improves payload capacity in aerospace, promoting sustainability and performance optimization.

The discussion highlights corrosion resistance, fatigue performance, and the availability of custom solutions from providers like Tencom, positioning pultruded fiberglass as a high-performance alternative to traditional materials in weight-sensitive environments.